NCAR PAN-CIMS instrument

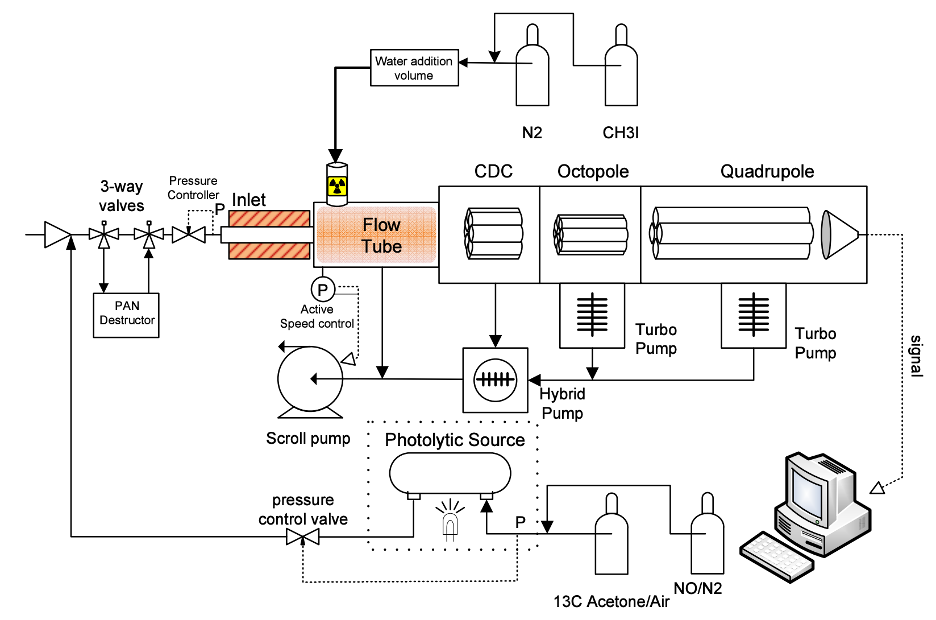

The NCAR PAN CIMS is a chemical ionization mass spectrometer and consists of five sections at successively lower pressures separated by a series of orifices (see instrument diagram in figure 1). The first stage is the thermal dissociation region, a thin walled 3/8 inch O.D. (0.8 mm wall thickness) PFA Teflon tube, inside of which the pressure is maintained at 140 torr by an in-line stainless steel pressure controller (MKS Instruments, model 640). To rule out potential surface reactions on stainless steel, a critical orifice made of PFA has also been tested as a replacement for the pressure controller, and no apparent difference in TD-CIMS detection sensitivity was observed for all species tested here. The last, 10 cm long, section of tubing immediately in front of the flow tube orifice is heated to 423 K, measured at the outside of the PFA tubing wall. The residence time in the heated inlet at its typical flow rate of 1.6 slpm is approximately 20 ms. A constant mass flow is allowed through a 0.86 mm diameter aluminum critical orifice into the flow tube. The flow tube is maintained at constant pressure of 20 torr by a dry scroll pump (model P16, Air Squared, Inc.) with actively controlled pumping speed (normally operated at ∼100 l min−1 ), designed to stabilize the flowtube pressure to better than ±0.1 torr. The iodide anions are produced in a 10 mCi (3.7 × 108 Becquerel) 210Po in-line ionizer (NRD, Inc. Model No. P-2021, half-life ∼138 days) by dissociatively attaching a thermalized electron to CH3I molecules as they pass through the ion source in a 1 slpm diluted mixture in N2 (∼2 ppmv). The ion-molecule reactions occur over the length of the flow tube and the resulting product ions are transmitted through a 0.74 mm diameter aperture into a collisional dissociation chamber (CDC). The octopole is biased to 2 volts higher than the flowtube voltage to provide a collision energy around 48 kcal mole−1 , so RC(O)O−(H2O)n can be effectively de-clustered. The CDC is maintained around 200 mtorr with a hybrid turbo pump (Alcatel model ATH 31+, 26–30 l s−1 ), The ions are then guided through the octopole, mass filtered in the quadrupole, and detected by an electron multiplier (Ceramax 7550M). The two final chambers, which contain the octopole and the quadrupole mass filter separated by a 3.2 mm diameter aperture, are pumped by 68 l s−1 (N2) turbo pumps (Varian V70LP). Background counts at the masses corresponding to PAN and its homologues are determined by pulling ambient air through a 2 m long stainless steel line filled with stainless steel wool heated to 423 K at flow rates of 2–5 l min−1 , which effectively destroys PAN species. This method (as opposed to using dry zero-air) has the advantage that the air matrix remains very similar to ambient air in the respective sampling region. In particular, humidity levels and VOC content are not altered significantly.

For calibration, we continuously add a known amount of isotopically labeled 13C-13C PAN produced photochemically from 13C labeled acetone and a known amount of NO in a photolysis chamber at 298 nm. The calibration signal is measured at m/e=61 and ratioed to the ambient PAN signal.

Figure 1: NCAR PAN CIMS Diagram

Figure 2: The NCAR PAN CIMS instrument installed on the NSF/NCAR C-130 aircraft. The installation fits into a single-bay rack.