Capabilities - Full Listing

Within the ACOM Engineering Support group, we have experience developing a variety of instrumental systems, ranging from small handheld instruments to FAA certified airborne rack based systems. We have a broad background with most types of instrumentation and sensors used in the atmospheric sciences - mass spectrometers, particle counters, optical remote sensing, REA sample devices, etc. - as well as full rack mounted systems and sampling inlets for various aircraft. Our goal as an engineering support group is to assist anyone in the atmopspheric research community (both inside and outside NCAR) who is interested in creating a new instrument or improving an existing instrument.

Our capabilities include:

- Complete systems design and overview, from initial design stage to final design review and fabrication

- Mechanical design, fabrication, and assembly

- Electrical systems design

- Printed circuit board design and PCB component installation

- PIC embedded microcontroller and National Instruments Labview softare for data acquisiton and system control

- Hazards, electrical, and mechanical systems analysis documentation for Part 25 FAA certification

- Electrical wiring and assembly

- Field support, both for mechanical/electrical installation and for instrument operation

- Experience with numerous research aircraft: NCAR C-130, NCAR Gulfstream GV, NOAA P-3, NASA GlobalHawk, NASA WB-57

Solidworks CAD Design

We have extensive experience with Solidworks CAD and FEA software for creation of 3D CAD models, part drawings, assembly drawings, and finite element stress analysis models.

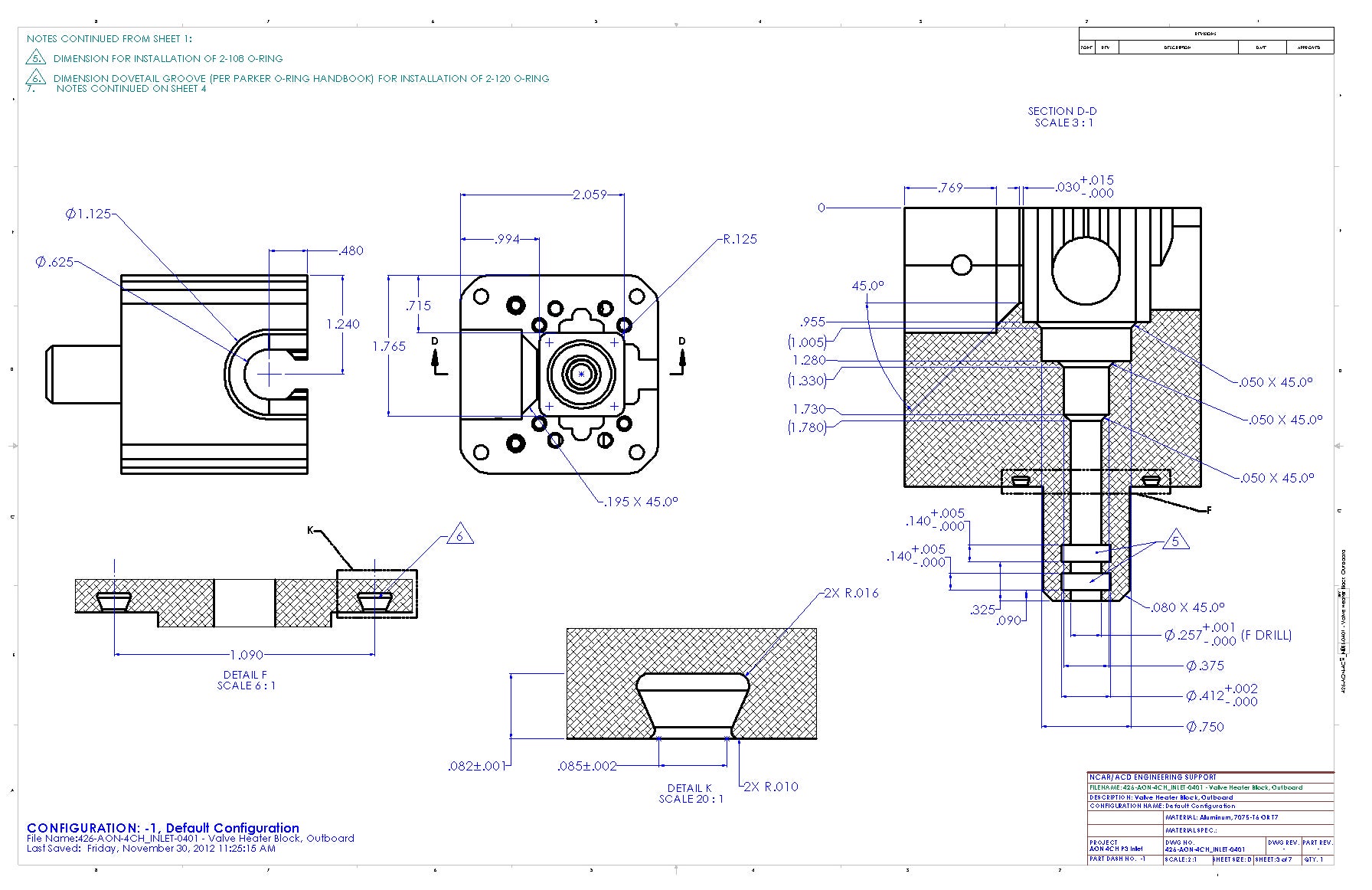

Part Drawing Example (AON Converter Oven Valve)

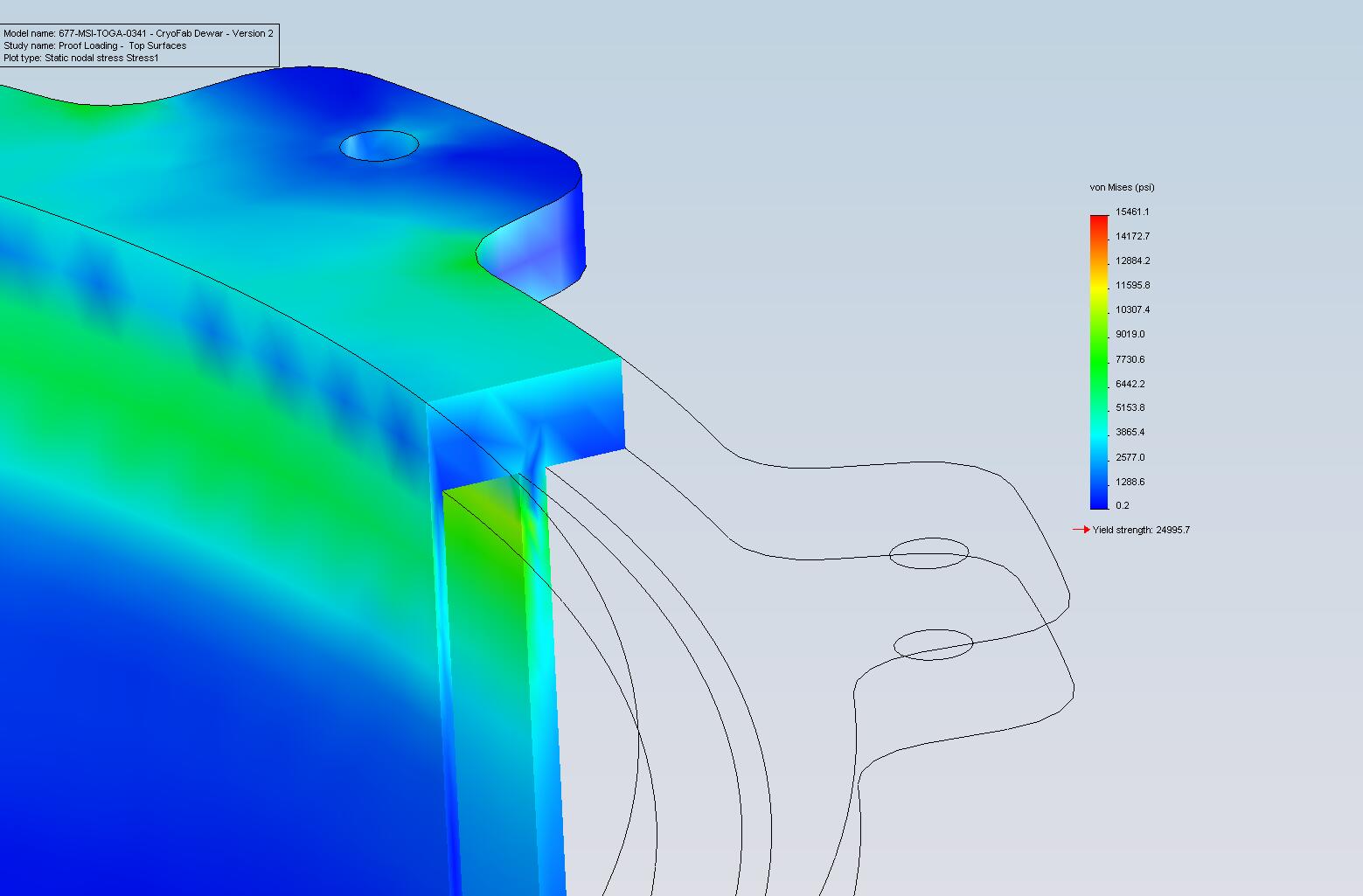

FEA Stress Analysis Example (TOGA Pressurized Dewar)

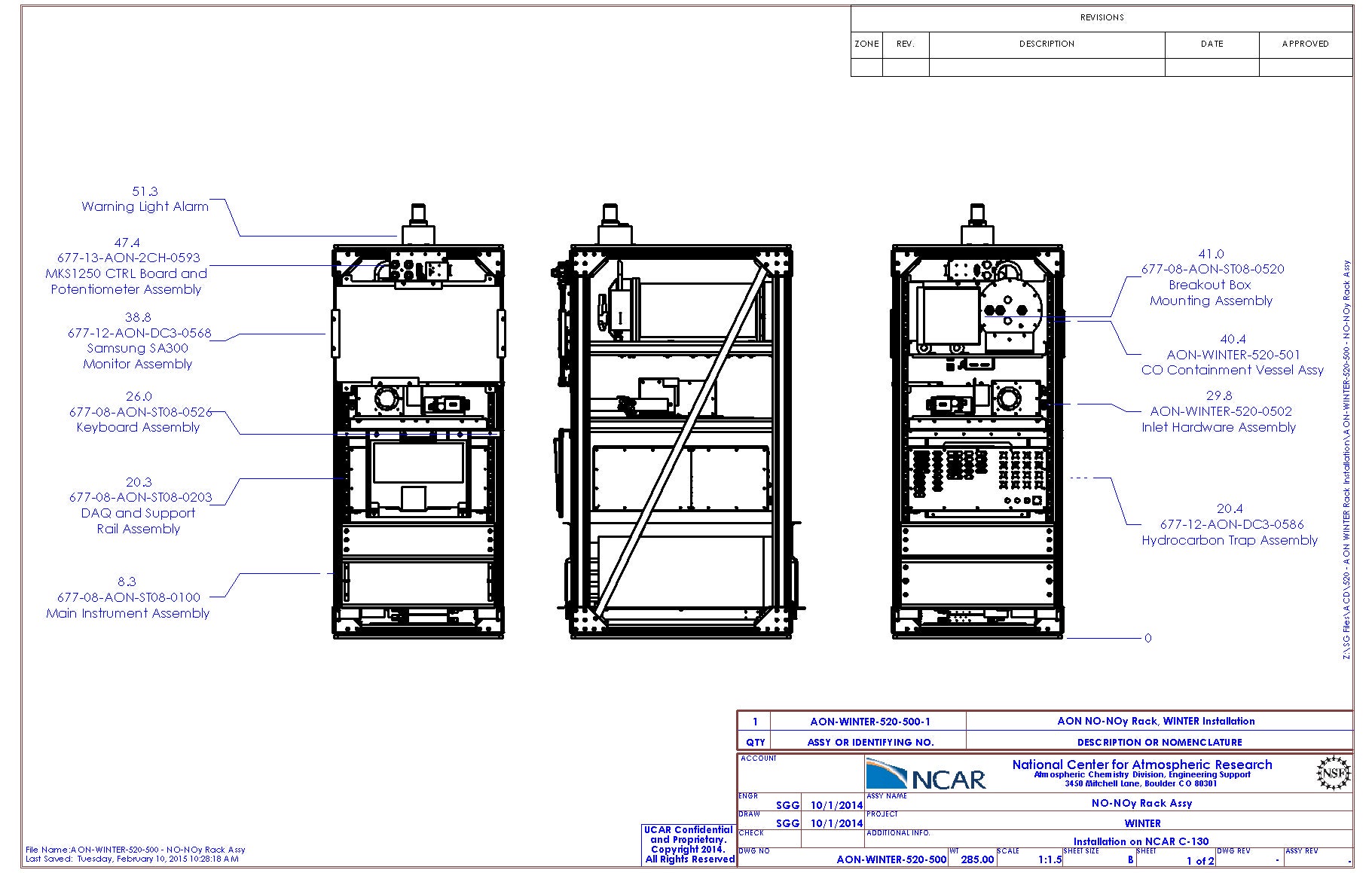

Assembly Drawing Example (AON NO-NOy Rack Assembly Installation)

Documentation for FAA Certification

We have created numerous mechanical and electrical certification documents for aircraft instrument and inlet installation, and have experience with full electrical loads and system hazard analysis. Steve Shertz has additional training in aircraft airworthiness analysis and hazard documentation related specifically to FAA certified aircraft. We have experience with the requirements for FAA Part 25 airworthiness standards certification for research aircraft, and we work extensively with the NCAR aeronautical engineer and DER certification staff to understand certification requirements for different types of instruments and aircraft.

Example Structural Analysis Document: AON P-3B Four Channel NOx and O3 Installation

Example Hazards Analysis Document: Airborne PAN-CIMS Instrument Specific Safety Assessment and Hazard Disclosure

Example System Integration Document: Airborne PAN‐CIMS System Integration

Labview and PIC Data Acquisition Software

Our group uses CCS C Compiler microcontroller development software for creation of embedded PIC-type data acquisition programs. For software to control instruments and data acquisition hardware, we use National Instruments Labview software and hardware for development of data acquisition systems and communication programs. We have experience with National Instruments analog and digital I/O boards, National Instruments USB DAQ hardware, PC104 systems, Labjack USB data acquisition systems, and custom data acquisition printed circuit boards.

Field Support

We have provided field support both at the NCAR Research Aviation Facility during instrument testing and installation, and also at remotes sites ranging from rainforests to high latitude Arctic installations, and we have the scientific background to provide instrument operation support during flights and field campaigns. Members of our group have provided installation and field support for for the following field projects in the last several years - HIPPO (multiple locations), OASIS (Alaska), MIRAGE-Shangai (China), SOAS/NOMADSS (Tennessee/Alabama), ATTREX (Edwards Air Force Base, California), and FRAPPE (Colorado).

PCB Design and Fabrication

Using Altium Designer and Express PCB software and commercial custom printed circuit board vendors, we can create multi-layer printed circuit boards and install electronic components on these boards. Using this PCB software, and working with quick-turn PCB vendors, we can quickly create a prototype circuit board design, and can fabricate custom circuit boards in small quantities.

Electro/Mechanical Assembly and Wiring Support

Our group has a designated electronics technician with experience in the following areas: circuit board component installation, power and instrument wiring, requirements for certified wiring and aircraft specific electronics, and general electronics and electrical assembly. In addition, we have experience with general mechanical assembly for ground based and airborne instrument.

Machining and Fabrication Services

Our on-site facilities include a small machine shop for basic fabrication and assembly, and a part-time machinist is available for small projects or mechnical modification of existing components. For larger or more complicated machining projects, we have established a close working relationship with NCAR's Design and Fabrication Services (DFS) division. DFS is a full machine shop with multi-axis CNC lathes and milling machines, certified welding facilities, and sheet metal fabrication, as well as dedicated engineering staff and material procurement specialists. The DFS staff have extensive experience working on custom aircraft hardware, as well as knowledge of proper design and assembly techniques for research instruments. More information on the DFS facility can be found here: Design and Fabrication Services

Research Aircraft Experience

Our group has installed instruments on most of the typical research aircraft in use for atmospheric research field missions