TOGA

The Trace Organic Gas Analyzer

Our research group has been deploying fast online gas chromatograph/mass spectrometers (GC/MS) since the 1990s. The Trace Organic Gas Analyzer (TOGA) was completed in 2012 and is certified for deployment on the NSF NCAR Gulfstream V (GV) and C-130.

TOGA provides near-continuous real-time atmospheric mixing ratios of an extensive and growing list of volatile organic compounds (VOCs) in the C1-C10 molecular structure range. The list includes alkanes, alkenes, chlorofluorocarbons, halons, nitrates, nitriles, sulfides, alcohols, ketones, aldehydes and ethers. Typically, a subset of some 60-70 unique trace gases are measured, with sufficient sensitivity to measure trace species in the remote background atmosphere and dynamic range to measure in highly polluted regions.

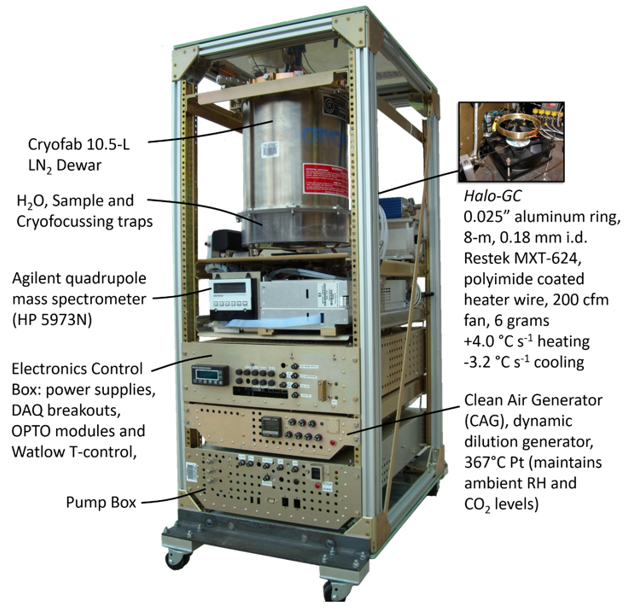

The HAIS TOGA is contained in a standard GV rack and consumes ~1 kW of power. The primary hardware components of TOGA are the pump box, clean air generator/calibrator (CAG), electronics box, mass spectrometer (MS) electronics/flow controllers, MS chamber and high vacuum pumps, and LN2 Dewar assembly. These are shown in Figure 1.

Figure 1. Diagram of the HAIS Trace Organic Gas Analyzer (TOGA).

The TOGA inlet is a constant mass flow design to mitigate the intrusion of aerosols and allow for calibrations and system blanks through the inlet and associated tubing.

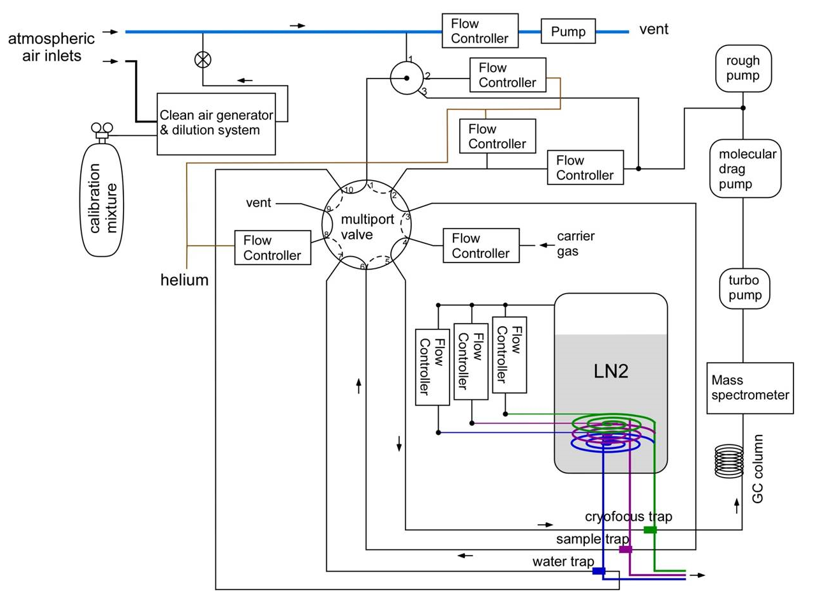

A cryogenic preconcentrator, consisting of a custom-built LN2 dewar and a system of traps, is used for water removal, sample enrichment and cryofocusing of trace constituents. Flow switching between traps is done via a heated (50°C) Valco 10-port valve. TOGA's flow system is diagrammed in Figure 2.

Figure 2. Flow system of the Trace Organic Gas Analyzer (TOGA).

A quadrupole mass spectrometer operating in selected ion monitoring mode is used to quantify individual compounds. High speed electronics allow the simultaneous measurement of several peaks with ~ 1-second peak widths. System calibrations and blanks are performed using a catalytic-clean air generator/dynamic dilution system with accurate (±1%) and precise (±1%) calibration gas delivery. The system operates continuously, allowing for frequent calibrations and zeros during flight.

Measurement Characteristics:

Overall estimate of uncertainty: VOC dependent, typically 20%.

Precision: 3% or less.

Response time: typically 35-second samples on a 2-minute cycle.